Solutions / Scanning 3D / Products and Applications

dPlusEPSC

|

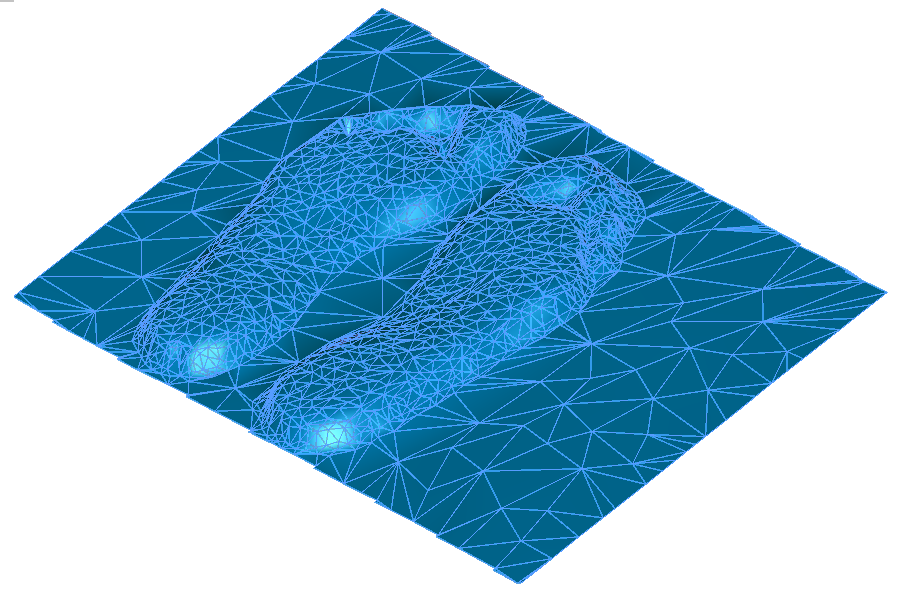

dPlusEPSC is a non-contact optical digitizing system, including the digitization equipment dPlus, positioning stand and control software. It is an ideal system for the complementing of CAD/CAM environments with an efficient way of measuring real object coordinates making it possible to integrate the reverse engineering component into the productive process. |

The digitization equipment measures 3D coordinates from the object surface and builds a mesh surface asnd extracts topological information like feature lines, using the auxiliary software dPlusMagic

The technology is based on light pattern projection and analysis of the object surface reflections by a high-resolution camera, with Reverse patented algorithms.

Increase your company efficiency and competitiveness: the use of dPlusEPSC allows for shorter product development times and makes quality control a much more robust and less costly process as the need for complex mechanical setups is eliminated.

Applications:

- generating CAD data from objects

- transferring model modifications to CAD in product development

- comparison between real object and CAD model for quality control

- deformation analysis of parts subject to strain

Characteristics:

- portable and easy to setup on any standard tripod

- up to 750 000 point measurements for each view

- up to 16 points per mm2

- virtually unlimited number of views

- 0.2 mm accuracy

- objects can vary from 1cm up to 2m (depending on resolution)

- fast digitization of 1 view from 4s to 30s (depending on resolution)

- robust even in difficult light conditions

- several standard outputs or export formats

Operation:

- image acquisition is performed by positioning the sensor in various locations (views) to obtain a global reconstruction of the object

- sophisticated algorithms perform fast and accurate measurements producing a cloud of points (COP)

- the system offers a unique combination of different measurements: full surface, single point and parametric feature measurements

- the system includes a complete software package which assists the user in the 3D digitizing process, including the image acquisition and 3D analysis steps